|

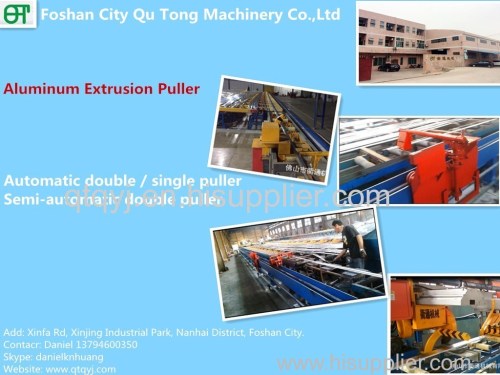

Foshan City Qu Tong Machinery Co.,Ltd

|

Aluminum etrusion double / single puller

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

high quality automatic double and single alumunum extrusion puller with auto saw

▲Constant pulling force, the traction profiles are guaranteed not to be deformed by excessive traction.

▲The tractor keep pace with the aluminum extrusions.

▲Double track, to ensure tractor working smoothly and steadily.

▲Automatically pick up the front/back kerf of the aluminun extrusions. And cut the aluminum extrusions continuously, to improve the efficiency and reduce the reject rate.

▲Multiple operating model, apply to all kinds of aluminum profiles

▲Adopt frequency conversion technology ,to keep the stability of the work, energy saving and environmental protection.

▲Adopt automatic control, reducing labor intensity.

2,working principles

▲Pull torque: To set torque (the HMI sets the torque) according to the production process. According to determined torque, the tractor machine keep pace with the extrusion profiles.

▲Two tractors convergence: the rear tractor(tractor B) accroding to the displacement sensor and the speed of the front tractor(tractor A) calculate the distance between the tractors, then the rear tractor (tractor B) adjust its speed to achieve the two tractors convergence smoothly.

▲Clamping jaw: tractor A apply the eccentric wheel principle, and tractor B apply hydraulic cylinder to clamping material.

▲Traction drive:tracting by two independent wire rope or two chains to avoid the sudden stop.

▲Program control: 4 sets of PLC with HMI 485LINK, to make the whole equipment operated automatically.

▲Profiles cutting: according to the distance from the extrusion press to the tractor A, figure out the length between the profile and tractor A's sawing machine, so as to saw at the seams of two profile during the extrusion process.

▲Mode setting: according to the aluminum rod conveying of the extruder, extrusion siginal and the HMI setting, to achieve the implementation of one rod one cut or more rods one cut.

.jpg)